7 Simple Techniques For Motorcycle Parts New Zealand Specialists

Table of ContentsMotorcycle Parts New Zealand Specialists Things To Know Before You BuyThe Buzz on Motorcycle Parts New Zealand SpecialistsFascination About Motorcycle Parts New Zealand SpecialistsWhat Does Motorcycle Parts New Zealand Specialists Do?Motorcycle Parts New Zealand Specialists Can Be Fun For AnyoneRumored Buzz on Motorcycle Parts New Zealand SpecialistsMotorcycle Parts New Zealand Specialists - An OverviewAll About Motorcycle Parts New Zealand Specialists

Reach out to one of our experts today.CNC machining innovation is rapidly coming to be the centerpiece of numerous various manufacturing procedures around the world as a direct result of its many advantages over various other approaches. In addition, the sectors that produce bikes have gotten on board with this trend. The most cutting-edge firms are now developing their engine components and wheels making use of machining methods originally created for motorcycle components.

On the various other hand, the effects of market are the key focus of this write-up. Allow's get straight right into it. You may be questioning why we use. It is not difficult to fathom the variables that resulted in this result. Since we have your focus allow us clarify the reasoning behind this contemporary development in the motorbike manufacturing industry.

Get This Report on Motorcycle Parts New Zealand Specialists

In enhancement, you have total control over the look of the components, also down to the min information. Occasionally, motorcyclists may choose to spruce up their experience by mounting aftermarket parts or changing the bike's remodeling.

The Single Strategy To Use For Motorcycle Parts New Zealand Specialists

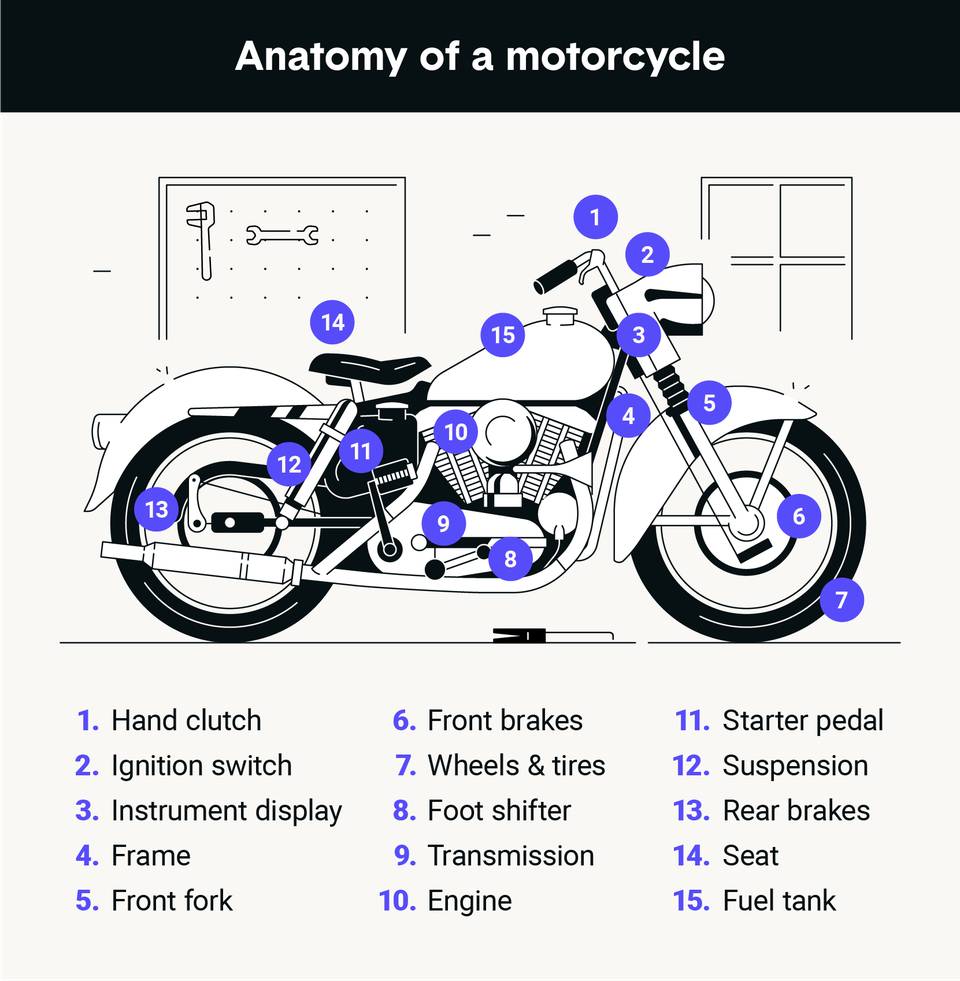

CNC machining might be used to make mostly all of a motorbike's metal and plastic parts. To continue, we'll go over numerous machined components for bikes. Unlike those on cars and trucks, wheels on bikes tend to be much more obvious. Consequently, the bike's appearances may be improved with the ideal personalization of these wheels.

Milling procedures are utilized to acquire the wanted degree of wheel modification. One more aspect of the motorcycle that might be individualized is the tires.

The Single Strategy To Use For Motorcycle Parts New Zealand Specialists

When it pertains to an automobile (or a motorbike), one of the most crucial component is the engine. A number of people mention it as the "heart" of the auto. On the various other hand, the camshaft, the cylinder head, and the pistons often tend to be intricate and require designs with a high level of precision.

Lights is an additional complex element of personalization. Usage just high-grade things, nevertheless, considering that these lights are vital for the safety and security of motorcyclists and other chauffeurs or individuals on the road, particularly during the night. Bike headlights have three almosts all: the bulb, or source of light, the lens, and the housing. In certain, we customize the lens and the housing.

Milling processes with a remarkable finish would certainly lead to the lenses having a reflective quality that is comparable to that of a mirror. The cover, on the various other hand, is not made up of delicate products; rather, it is constructed out of tough polymers that can be machined into more elaborate patterns.

The Ultimate Guide To Motorcycle Parts New Zealand Specialists

They often have sophisticated geometries with a wide range of min information. Motorcycle producers typically cast these elements, yet only for the production of bespoke parts. CNC machining is the technique of option when creating special pieces. Machining on 5 axes in go to this web-site today's world is the means by which any type of design form may be recognized.

Pick Runsom for your personalized motorbike parts! We have the capacity to fabricate difficult and fashionable components making your motorbike matchless.

Right here are a couple of instances of steels typically used in motorbike part machining. Aluminum is the main product utilized by business specializing in generating custom-made motorbike parts to create many of these components - Motorcycle Parts New Zealand Specialists.

Zinc describes another steel that is very light in weight and has excellent discover here machining qualities as a result of its high mechanical toughness. This material may be formed right into virtually any type of shape and maintains its dimensions well. Even mission-critical parts that need a high degree of accuracy may benefit from their use.

Motorcycle Parts New Zealand Specialists Fundamentals Explained

One more metal that sees hefty usage in the manufacturing of CNC-customized components is magnesium. It is among the lightest metals that are currently easily accessible and has exceptional machinability attributes and stamina appropriate with its low weight. Among the drawbacks of magnesium is that its dirt may quickly ignite.

Their most common use in generating numerous bike elements is fasteners, such as screws and bolts. Their reduced sensitivity to oxidation and deterioration makes them suitable for this usage.

Motorcycle Parts New Zealand Specialists Can Be Fun For Everyone

It seems that CNC turning and milling are the foundational processes. Full Report In addition, it needs keeping bars of product, most typically plastic or steel, in setting and after that turning a cutting device to remove areas of the product as the material is turned.

These methods are similarly crucial and create elements with high precision and constant top quality. The procedures help boost the total top quality of the machined motorcycle components.

A Biased View of Motorcycle Parts New Zealand Specialists